CONDENSING VENT

INNOVATION

ICC is a market leader in venting manufacturing. We apply leading-edge technology and engineering to find innovative solutions for everyday problems.

Our innovative components are conceived with the goal of faster, easier assembly, which is the best way to reduce labor cost and installation errors. All ICC products are built to meet modern needs in the harshest environments.

APPLICATIONS

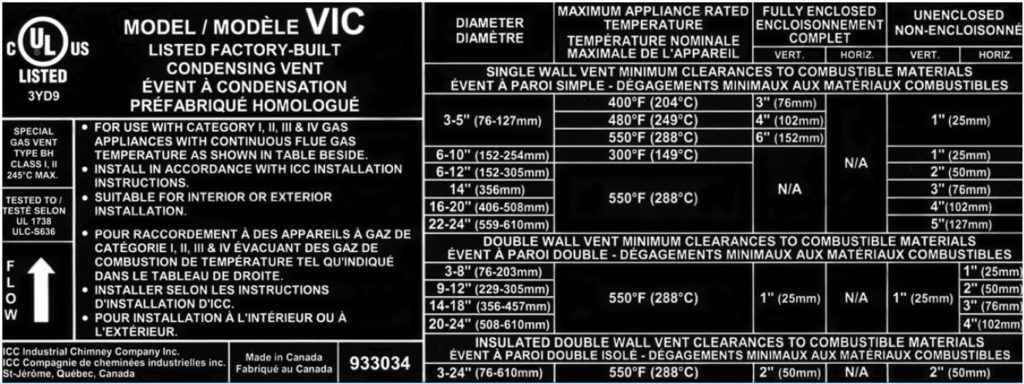

ICC Model VIC is a tested single wall, double wall, or insulated double wall vent system for condensing or near condensing appliances. Tested and listed to UL 1738 / ULC S636.

ICC Condensing Vent can be used in the following applications:

- Category I, II, III and IV gas fired appliances producing a maximum flue gas temperature of 550°F

- BH gas vent for appliances producing a maximum flue gas temperature of 550°F

- Appliances that produce condensation in the exhaust stream

VIC Listing Label

Documents

| CATALOGS AND BROCHURES |

|---|

| Installation Instructions – Chimney |

|---|

| Order Forms |

|---|

ENGINEERING

Upon request, our engineers will analyze schematic drawings and appliance data to determine the correct size and parts for any venting system. We will also provide detailed drawings and a parts list to facilitate installation.

CONSTRUCTION

VIC’s inner liner is constructed of either super ferritic type AL29-4C stainless steel or out of type 444 stainless steel. Both alloys meet the requirements of the UL corrosion resistance test. When a double wall system is specified, the outer casing will be made of a type 430 stainless steel.

The system is available in the following configurations:

- Single wall – for breeching and connecting multiple appliances together. It is lightweight and easy to install. It is recommended that single wall VIC be installed inside the building or where ambient temperatures remain above freezing.

- Double wall – improves heat retention in the flue. This increases draft strength and can reduce clearance to combustibles in some cases. Double wall also has a lower impact on the surrounding environment’s temperature (e.g. mechanical room). It is approved for interior and exterior installations.

- Double wall insulated – the best choice for exterior installations in cold weather climates. The insulated casing minimizes heat loss and promotes increased draft. The inner liner of 5″-16″ diameter VIC is either Tungsten Arc Welded or Laser welded. Diameters 18″-24″ are Tungsten Arc Welded. Both Laser and Tungsten Arc welds are butt welds. Butt welding minimizes the impact on the steel, resulting in a smooth and corrosion resistant seam.

VIC incorporates a silicone gasket which creates a seal that is both gas and water tight. The silicone seal drastically reduces installation time by eliminating the need for sealant to be applied in the field. VIC locking bands hold the sections together without the need of additional screws. The captive nut / bolt system is exceptionally strong and results in a straight, secure run of pipe.

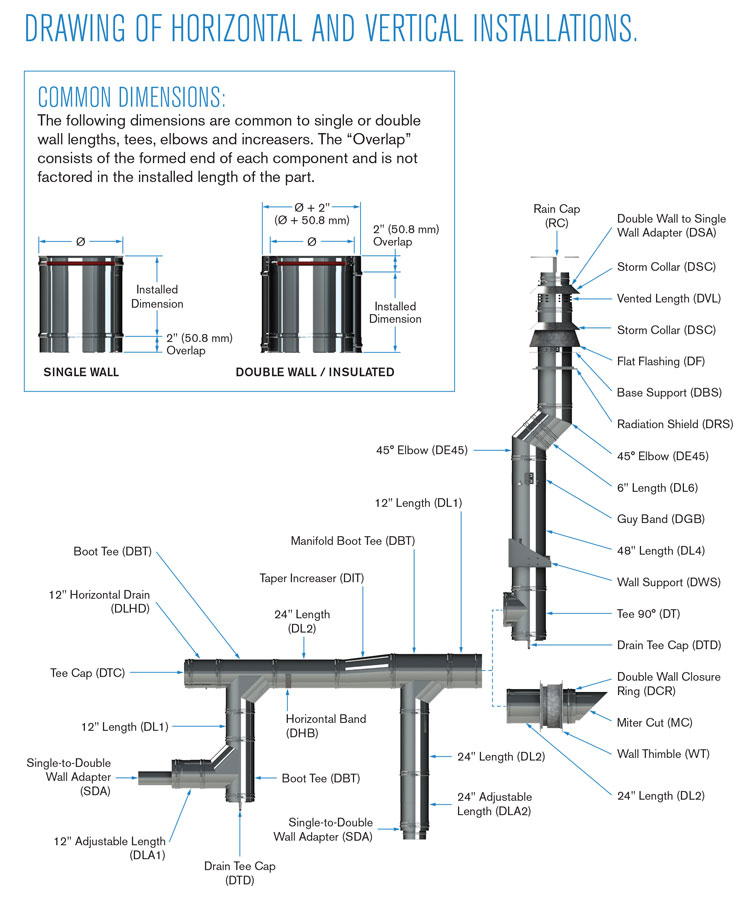

INSTALLATION

VIC fits right the first time thanks to tight tolerances and precision manufacturing. Our factory installed silicone gasket eliminates the requirement for sealant to be applied on site, and ensures a gas and water tight seal.

Lengths are secured with heavy-duty locking bands that draw the lengths together. Our locking bands have a captive nut and bolt, reducing the likelihood of missing hardware. The result is fast, trouble free installations.